Being MotionCables a cable manufacturer we rely on our previous experience to de-fine a series of parameters that allow the end user to determine which cable is best for the application in which it is intended. To drive this choice, in addition to the lev-els of performance, MotionCables also de-fines a number of salient features based on four fundamental aspects: oil re-sistance flame resistance, type of move-ment, and flexibility. By defining these im-portant features we provide our custom-ers a reference point from which stating the correct choice of cable.

| level | Test Methods | BP | DP | HP |

|---|---|---|---|---|

| O-I | VDE 0281 Part 1 In oil for 7 days @ 60°C ± 30% Untensile strength ± 30% Unaged Elongation |

postive | postive | postive |

| O-II | UL Oil Res I In oil for 4 days @ 100°C 50% Untensile strength 50% Unaged Elongation |

postive | postive | postive |

| O-III | VDE 0472 Sect. 803B In oil for 7 days @ 90°C ± 25% Untensile strength ± 25% Unaged Elongation |

postive | postive | postive |

| O-IV | UL Oil Res II In oil for 60 days @ 75°C 65% Untensile strength 65% Unaged Elongation |

postive | postive | postive |

| O-V | VDE 0472 Sect. 803A In oil for 7 day @ 100°C ± 25% Untensile strength ± 25% Unaged Elongation |

- | - | postive |

| level | Test Methods | BP | DP | HP | |

|---|---|---|---|---|---|

| F-I | FT2 (UL 1581): Horizontal Flame Test Perform flame spraying for 30 seconds. The cable must not emit flames or luminous particles |

postive | postive | postive | |

| F-II | IEC 60332-1-2 / Vertical Flame Test After burning for 60 seconds, the cable must go out by itself. |

postive | postive | postive | |

| F-III | VW-1 (UL 1581): Vertical Flame Test The cable must self-extinguish with five flame programs of 15 seconds. The cable must not emit flames or luminous particles. |

postive | postive | postive | |

| F - IV | FT1 (UL 1581): Vertical Flame Test Three 60-second flame programs. The cable must self-extinguish. The cable must not emit flames or luminous particles |

postive | postive | postive | |

| F-V | IEC 60332-3-24 Exposure to flame for 20 minutes, the damage should not exceed 2.5 metric tons. |

UL 1581: Vertical Tray Test Expose to flame for 20 minutes. The cable must not emit flames or luminous particles |

- | - | - |

| level | Test Methods | BP | DP | HP |

|---|---|---|---|---|

| M-I | Cable Chain Test (MotionCables method) Length: 2000 mm Acceleration: 60 m/sec2 Speed: 600 m/min |

10.000 cycles | 5.000.000 cycles | 10.000.000 cycles |

| M-II | Cable Chain Test (MotionCables method) Length: 5000 mm Acceleration: 40 m/sec2 Speed: 300 m/min |

5.000 cycles | 5.000.000 cycles | 10.000.000 cycles |

| M-III | Cable Chain Test (MotionCables method) Length: 110000 mm Acceleration: 10 m/sec2 Speed: 180 m/min |

- | 3.000.000 cycles | 5.000.000 cycles |

| M-IV | Flexing Endurance Test EN 50289-3-9 Length: 5000 mm Acceleration: 40 m/sec2 Speed: 300 m/min |

- | - | 100.000 cycles |

| M-V | Repeated Bending Test EN 50289-3-9 Pulley Diameter: 3 x cable O.D. Rotation Angle: ± 135 ° Load: 1000 g |

- | - | 5.000 cycles |

| M-VI | Alternative cable torsion with tension Test EN 50289-3-10 Sample Length: 300 mm. Rotation Angle: ± 540 ° Load: 1000 g |

- | - | 5.000 cycles |

| Diameter range-Ø | Sample length | Bending angle |

|---|---|---|

| 5-50mm | 20-100mm | ±135° |

The test type stipulates that the cable is subjected to bending conditions (each bending condition is regarded as a cycle) according to different load parameters on the same cable. The maximum tensile load is 3000N. The maximum cable diameter is 50mm. The test is similar to DI VDL 0281 Part 2.

| Diameter range-Ø | Rotation angle | Sample length |

|---|---|---|

| 5-50mm | ±540° | 1000mm |

| 5-50mm | ±360° | 300mm |

The cable (or cable bundle) rotates according to the left and right angles while being pulled (F). Each complete reciprocating motion is regarded as a cycle.

| Operation process | Acceleration | speed |

|---|---|---|

| 5mm | 4G | 400m/min. |

Make the tested cable sample travel at different speeds with different accelerations (sometimes even sudden) to simulate pulling, twisting and bending operations. A part of the cable is fixed on a heavy object, and the rest is passed through two pulleys. Each run is regarded as a cycle.

| Operation process | Acceleration | speed |

|---|---|---|

| 2m | 6G | 600m/min. |

| 5m | 4G | 400m/min. |

| 13m | 2G | 300m/min. |

| 110m | 0.5G | 100m/min. |

| Diameter range-Ø | Maximum pulling force |

|---|---|

| 10–50 mm | 5T |

MECHANICAL TEST-ING Tensile & Elongation IEC 60811, DIN 53504, ASTM D412, UL 1581

ENVIRONMENTAL TEST-ING Air Owen Aging Re-sistance IEC 60811 - UL 1581

ENVIRONMENTAL TEST-ING Fluids Resistance IEC 60811 - UL 1581 - VDE 0472

LOW TEMPERATURE TESTING Cold Elongation Test IEC 60811 - UL 1581

LOW TEMPERATURE TESTING Cold Impact & Bend Test IEC 60811 - UL 1581

MECHANICAL TESTING Run Impact Test IEC 60811, DIN 53504, ASTM D412, UL 1581

CABLE CONSTRUC-TION Video Microscope UL 758 UL 1581

ELECTRICAL TEST Dielectric Strength EN 61196.1/11.3

ELECTRICAL TEST Insulation Resistance EN 61196.1/11.2

HD-608

ELECTRICAL TEST Capacitance, Inductance, Resistance EN 61196.1/11.3

ELECTRICAL TEST Attenuation, Cross Talk, Impedance EN 61196.1/11.8

EN 61196.1/11.9

SECURITY TEST Flame Resistant UL VW1 IEC 60332-1

EN 50265-2-1 CSA FT4

In our idea to keep things easy, one step cannot be done in this way.

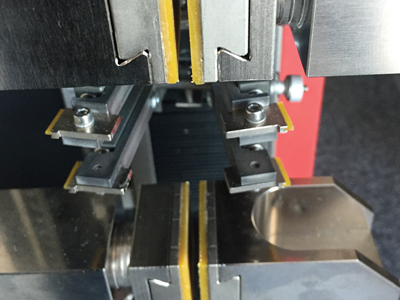

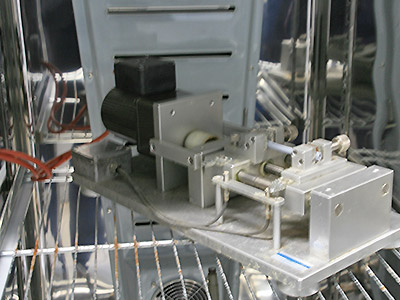

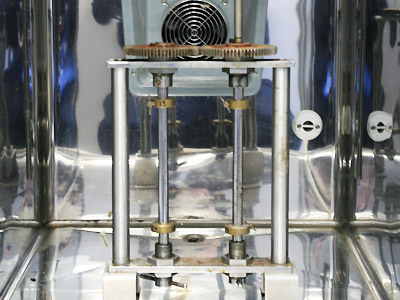

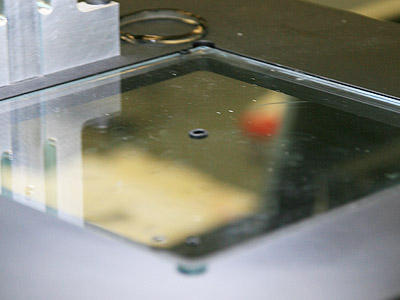

The MOTION LAB is where all the things has not to be easy, but has to be precise. Manda-tory. We are putting a wide and daily effort in the ever-evolving qualification and control of our products, materials, process of produc-tion. Our aim to distribute high quality prod-ucts have to cope with the fact that all has to be tested, tested and tested again. Quality is our key to success: we strongly believe that if a customer can cope with high-quality prod-ucts, on the spot service, deep technical ad-vice, so he will be bond to us and remain in our team for a long time.

As you are using our products we know that you depend on our quality, so we strive for the maximum. We validate designs of high performance industrial cables and accesso-ries through continuous testing. In the follow-ing pages a brief of some of the testing taking place at our state-of-the-art laboratories.